What Makes A Great SUP? 2025 Inside The Factory To Find Out Part2

May 16, 2025

Leave a message

Welcome back! In Part 1, we took you behind the scenes to see how Ridewave builds the strongest, most reliable inflatable SUPs from the ground up - from military-grade PVC materials, precision cutting, to seamless heat welding.

Now, it's time to explore the final steps - where the board takes shape with deck pads, valves, fins, and essential accessories. Then, we'll show you our rigorous quality checks, smart packaging, and smooth shipping - making sure your Ridewave boards arrive in perfect condition, ready to wow your customers in Europe, Australia, Russia, or wherever you sell.

Plus, learn about our flexible OEM and ODM services, tailored to help your brand stand out.

Let's dive in!

8. Fins, Valves, and the Small Details That Matter

Let's pick up where we left off. Your board now looks like a board - but it's not water-ready just yet.

We install universal fin boxes compatible with most aftermarket fins, plus custom options for brand-specific setups. Whether you need center slide-in fins, US boxes, or snap-lock side fins, we've got molds and stock ready.

Then comes the valve - a small part with a big role. Our boards use high-pressure inflation valves that are leak-tested and built to last 300+ uses. Easy to open, smooth to lock, and perfect for fast inflation and deflation.

Rigging: D-Rings, Handles, Bungees, and More

Want paddle holders, GoPro mounts, kayak seat attachments, or extra D-rings?

This is the moment to add them.

We use stainless steel D-rings, heavy-duty nylon bungee cords, and padded carry handles. These aren't glued randomly - they're measured and marked for symmetrical placement.

Rigging options can be tailored to fit:

Touring boards (extra cargo bungees)

Rental fleets (extra grab handles)

Yoga SUPs (minimal rigging for flat decks)

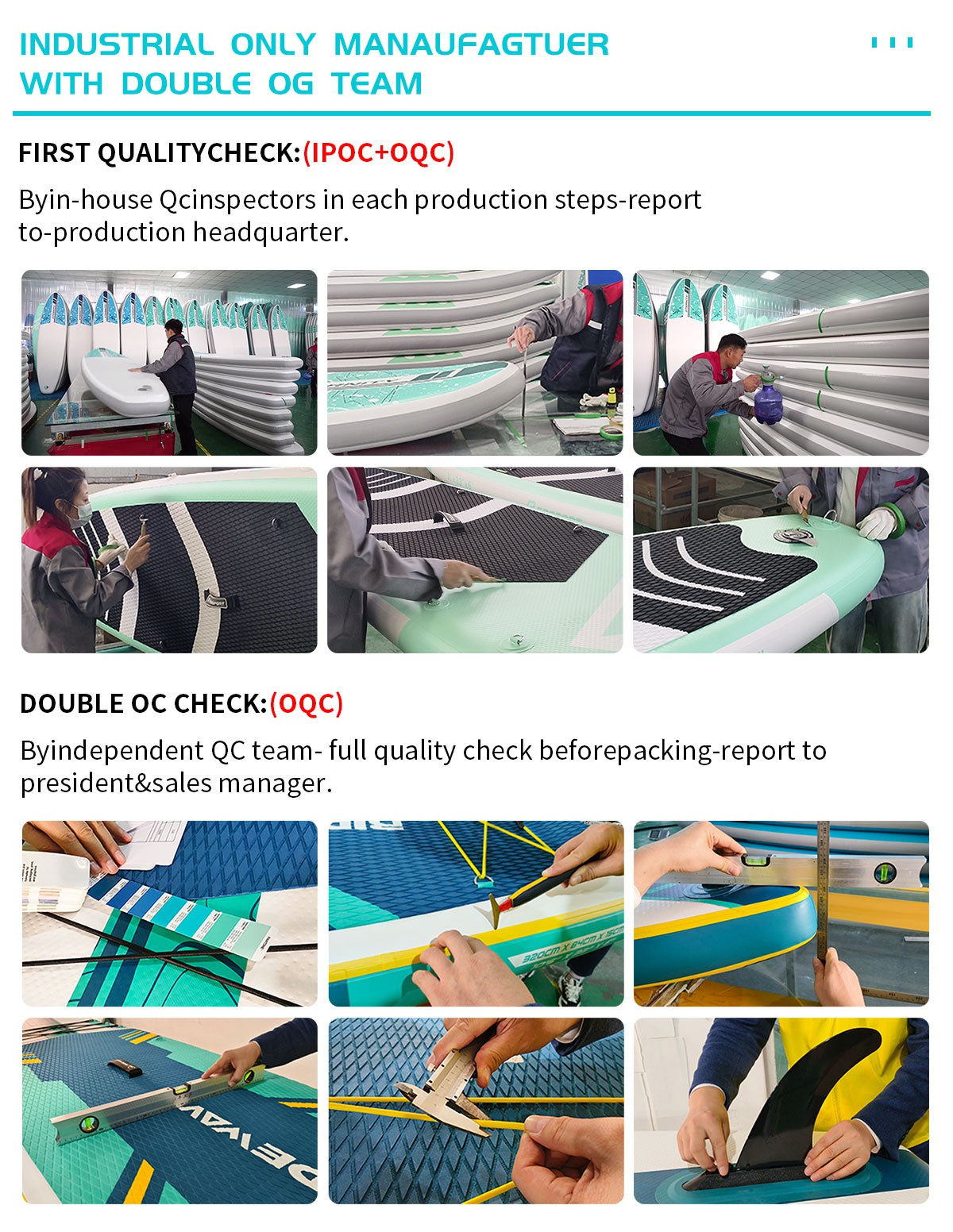

Time for a Quality Check

Before we box anything, we test it.

Each Ridewave SUP goes through a 24-hour inflation test. Boards are pumped to max PSI and left standing to check for leaks, warps, or seam failure.

Our QA team then inspects:

Surface smoothness

Print alignment

Weld consistency

Rigging strength

Failures don't ship. Period.

Accessory Kits: Ready for Retail

A SUP isn't just a board - it's a kit.

We assemble accessory packages to match your target customer. Standard sets include:

Adjustable aluminum or carbon paddle

High-pressure hand or electric pump

Leash

Repair kit

Carry backpack or wheeled bag

Want custom packaging with your brand? We do it. Barcodes? Instruction manuals? Promo inserts? You name it.

From China to Your Warehouse – Logistics & OEM Support

Last stop: shipping.

We vacuum-pack boards to reduce size by 60%, palletize per your request, and load into containers. FOB, CIF, DDP - we've done it all.

Need help with shipping docs or local compliance? Our logistics support team speaks your language - and your time zone.

More importantly, we offer full OEM/ODM services:

Custom board shapes and sizes

Brand-exclusive molds

Artwork and packaging design

MOQ-friendly private labeling

From first inquiry to final delivery, Ridewave helps you launch, scale, and repeatBefore we box anything, we test it.

Now you've seen the whole Ridewave process - from raw materials to global delivery. Whether you're sourcing for your retail brand, launching a new SUP line, or growing an outdoor gear empire, we're here to help.

Great boards don't happen by accident. They're built with purpose, by people who care, and in a factory that knows how to deliver.

Ready to make waves?

👉 [Visit ridewavesup.com and get a custom quote for your next order. Your board - your brand - starts here.]