What Makes A Great SUP? 2025 Inside The Factory To Find Out Part1

May 15, 2025

Leave a message

Ever wondered what's really behind a high-quality inflatable stand-up paddle board?

Spoiler alert: it's not magic - it's clever design, top-notch materials, and world-class factory execution. At Ridewave, we're not just building SUPs. We're building reliability - one board at a time.

Whether you're a distributor in Germany, a retailer in Australia, or a B2B buyer in Moscow, your needs are clear: consistent quality, fast lead times, and products that sell fast and ride smooth.

It All Starts with the Right Stuff

A premium board begins with premium ingredients. No cutting corners here.

At Ridewave, we use military-grade PVC for the outer skin. Why? Because it's:

UV resistant

Tear-proof

Long-lasting - even in salt, sun, and sand

Inside the board? That's where the magic happens. We use drop-stitch technology - thousands of tiny threads that lock the top and bottom together when inflated. This allows high pressure without bulging.

The result? A board that's rigid like a hard board, but rolls up when you're done.

Cut with Precision, Always

Each Ridewave board starts on a cutting table - with CNC laser precision.

Templates are loaded. Machines cut sharp edges and smooth curves. Whether it's our 10'6 all-round model or a 9' surf-style ride, each panel is identical to the last.

No uneven sizes. No weird shapes. Every board is production-grade perfection.

We also support custom shapes - touring noses, wider tails, child-friendly versions - whatever your market demands.

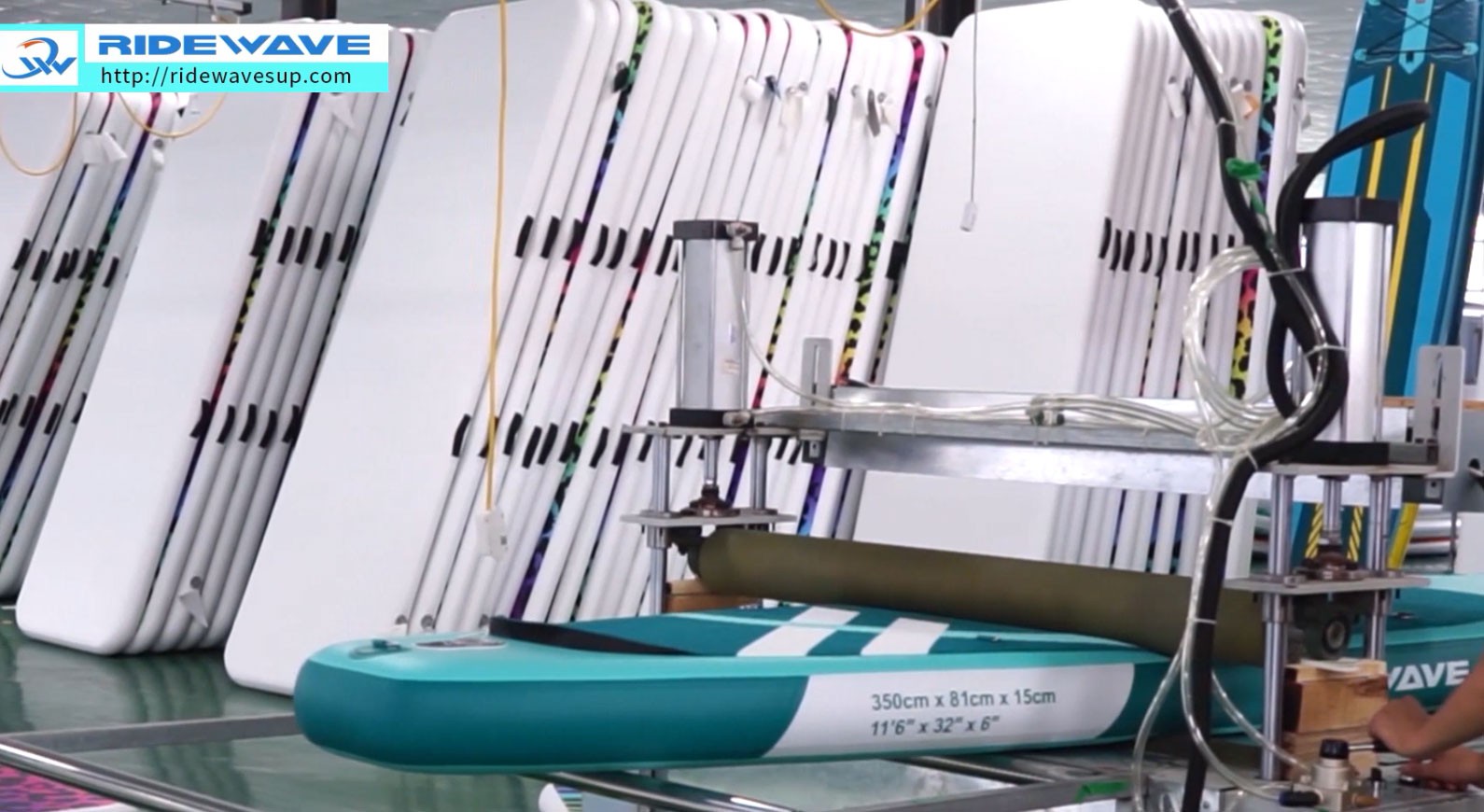

Layer by Layer – Stronger Together

Now, it's assembly time. Each board has multiple layers:

Inner drop-stitch core

Adhesive bonding film

Outer PVC armor

Optional reinforcement rails

We use heat + pressure to laminate layers, followed by manual inspection. Our team checks for wrinkles, trapped air, and misalignment. If it's not smooth, it's not shipping.

Result: boards that are smooth, flat, and ready to ride - season after season.

Heat Welding: Stronger than Glue

Some manufacturers still rely on glue. Not us.

Heat welding bonds the seams at the molecular level. That means:

No peeling

No chemical smell

No weak points at the seams

For our pro and mid-range boards, welding is standard. Entry-level models? We offer glued seams if you prefer a budget option - but 95% of our wholesale clients go welded.

Why? Because it lasts.

Deck Pads That Feel Just Right

Grip is everything. And so is style.

We use EVA foam deck pads, machine-cut and shaped for comfort and control. Choose from:

Diamond texture for grip

Crocodile skin for a premium feel

Brushed soft-touch for kids or rentals

Color options? Plenty. Grey, blue, black, dual-tone, or your custom brand color.

Every Ridewave board has a non-slip pad, kicktail (for surf control), and optional carry handle or camera mount slot.

Add Some Style: Branding & Printing

This is where your brand comes to life.

We offer:

Silkscreen prints for logos

Heat-transfer graphics

Full digital board art from tail to nose

Want to launch your own line? We can create artwork with your logo, your color theme, even your box packaging.

Or stick with our Ridewave line - sleek, recognizable, and surf-approved.

So far, you've seen the backbone of a Ridewave board - how we choose our materials, shape them with precision, and bond them for long-term performance. It's a lot of work, but it's what makes the difference between a board that just looks good and one that sells well, lasts long, and earns repeat buyers.

From military-grade PVC to seamless welding, every Ridewave SUP is designed for real-world use - and real B2B business.

But wait - we're not done yet.

In Part 2, we'll walk you through the final stages: from fin boxes and valve systems to accessories, quality checks, global shipping, and full OEM/ODM support. You'll see how we turn raw boards into retail-ready packages that ship worldwide - and keep your customers coming back for more.

👉 [Stay tuned for Part 2 – It's where things really come together.].