Ridewave's Manufacturing Strength: Built for B2B Growth

Ridewave's factory was established in early 2008 and is located in Weihai, China - one of the leading manufacturing hubs for water sports equipment. Our facility specializes in producing high-performance inflatable paddle boards (SUPs), inflatable kayaks, and other custom water sports gear for B2B clients worldwide.

Equipped with cutting-edge production technologies such as precision heat-welding machines, digital cutting systems, auto screen printers, and advanced drop-stitch lamination lines, Ridewave ensures consistent quality, durability, and customization for every board.

In March 2024, Ridewave expanded its production capabilities with the launch of a second factory, introducing next-generation automation, a streamlined QC system, and a highly skilled production team. With two modern facilities in operation, Ridewave now delivers a monthly output of 30,000–40,000 units, supporting both small MOQ and large-scale OEM/ODM orders with fast turnaround.

As an original manufacturer, we give paddle board brands, rental businesses, and distributors full control over design, branding, and packaging-making Ridewave your ideal long-term partner in the global SUP market.

SUP Factory Introduction

Ridewave Manufacturing Capacity

With two advanced factories operating in China, Ridewave has built a scalable and efficient production system to meet the growing demands of global paddle board businesses.

Total Production Lines: 9

Monthly Production Capacity: 50,000–70,000 inflatable SUPs and related water sports products

Our facilities are equipped with the latest in heat-bonding, drop-stitch lamination, digital cutting, and auto-printing technology, enabling us to handle both high-volume orders and low-MOQ custom projects with consistency and speed.

Our Expert Team

At Ridewave, we combine manufacturing power with deep industry expertise to ensure every board meets the highest standards in performance and durability.

400+ Skilled Workers

25 Dedicated Quality Control Inspectors

5 Professional SUP Designers

20 Merchandisers & Sourcing Experts

30 Sample Development Workers

From concept design to mass production, our experienced team supports you at every step to bring your brand vision to life.

Beyond In-House Production: Strategic Partner Network Across China

In addition to its own state-of-the-art factories, Ridewave works closely with a trusted network of sub-contractors across China, enabling us to scale production flexibly and deliver over 3 million units annually for global clients.

All outsourced manufacturing partners are carefully selected and closely monitored by Ridewave's internal quality control team. We ensure that every paddle board-whether produced in-house or externally-meets our strict quality standards and is delivered on time.

Our selection process for partner factories considers various factors, including:

-

Production capacity

-

Material sourcing standards

-

Labor skills and management efficiency

By combining our own manufacturing strength with a reliable sourcing network, Ridewave offers a complete solution: we are not only a manufacturer, but also a strategic sourcing agent for your SUP and water sports product needs in China.

Whether you're looking for OEM/ODM production, supply chain support, or rapid capacity expansion, Ridewave is your dependable partner in building a successful B2B paddle board business.

SUP Factory Production Equipment

Technology-Driven Production: Investing in Precision & Performance

At Ridewave, we continuously upgrade our manufacturing capabilities with advanced technologies to ensure higher efficiency, consistent quality, and faster turnaround for our global clients.

Every year, we invest over US$100,000 in equipment maintenance, process optimization, and the adoption of new production technologies. Our goal is to stay at the forefront of the inflatable paddle board industry by combining skilled craftsmanship with automation.

Some of the key machines we use include:

-

Laser-Cutting Machine for precision material shaping

-

32 Auto-Templating Machines to streamline consistent panel design

-

3 Auto-Cutting Machines for high-speed fabric accuracy

-

3 Auto Fabric & Drop-Stitch Spreading Machines to reduce manual handling

-

4 Auto Valve & Fin Placement Machines to improve sealing precision and efficiency

This ongoing investment allows us to maintain a strong balance between high-volume output and high-performance quality. Whether you're ordering 300 units or 30,000, Ridewave delivers with scale, speed, and reliability.

SUP Factory Quality Inspection

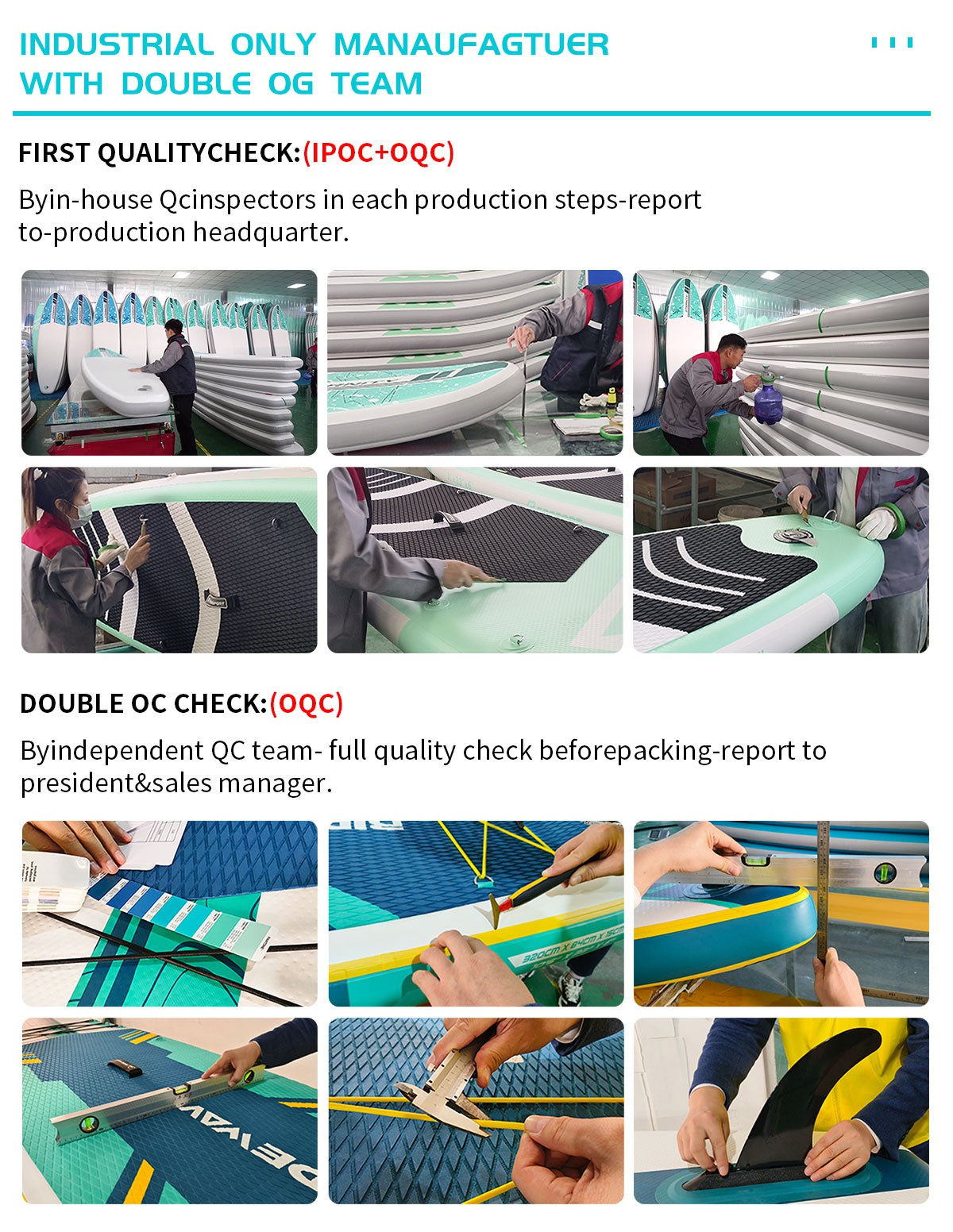

Strict Quality Control at Every Stage

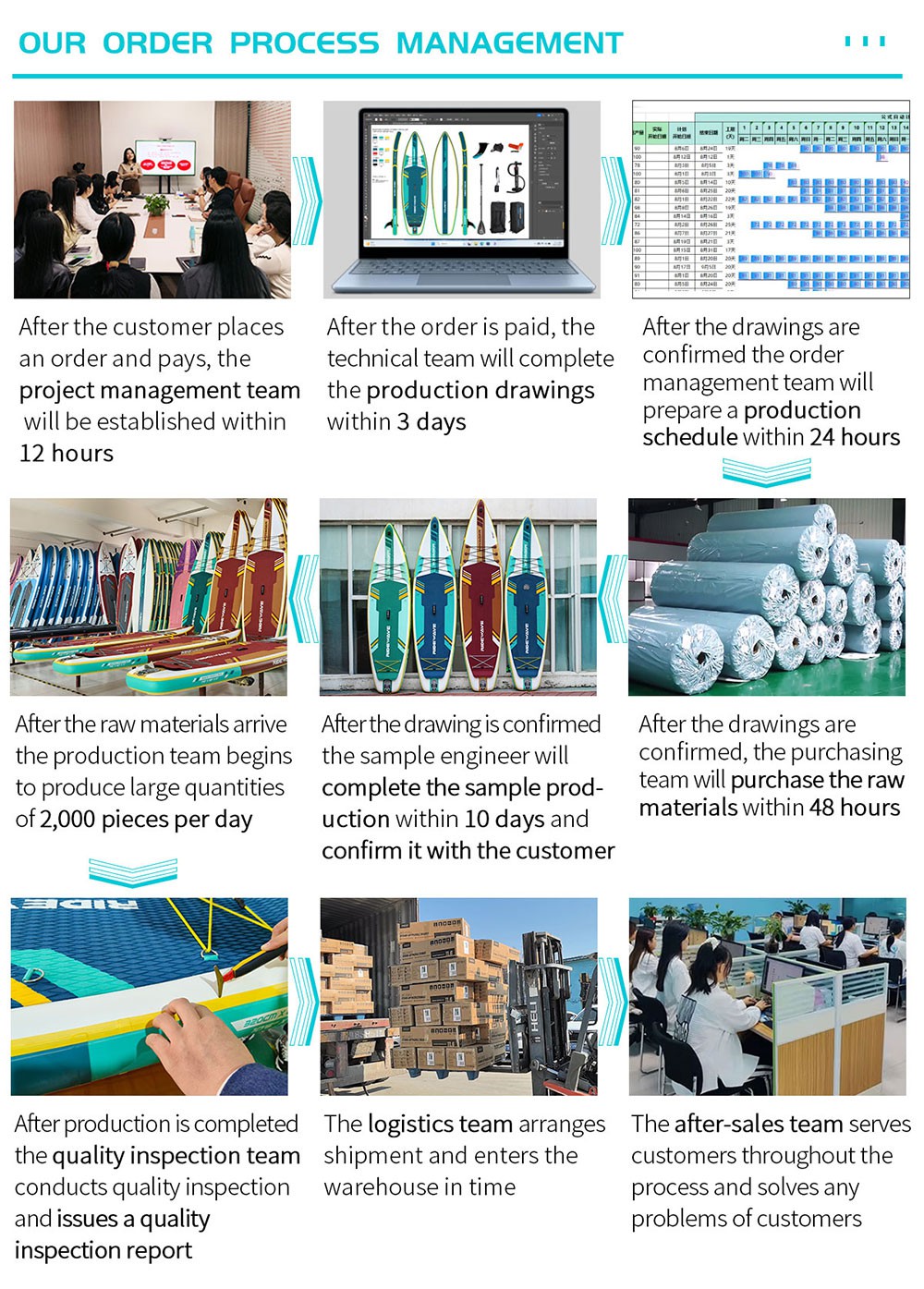

At Ridewave, product quality is at the core of everything we do. Our experienced QC and QA teams manage a comprehensive quality control system that ensures every paddle board meets international standards before it reaches your hands.

We implement strict checks throughout the production process:

-

Material Inspection: Fabric, drop-stitch core, valves, and accessories are inspected before cutting and assembling to avoid early-stage errors.

-

Pre-Production Meeting: Each new model starts with a detailed meeting to align all departments on technical files, construction methods, and customer requirements.

-

First-Piece Inspection: Our team checks the first assembled piece to detect any potential issues at the earliest stage.

-

Mid-Production Inspection: Ongoing checks during lamination, printing, and bonding processes help control consistency.

-

In-Line Quality Control: Continuous monitoring during assembly ensures defects are corrected immediately-before they move to the next stage.

-

Final Inspection Before Shipment: Every board is carefully inspected for air-tightness, shape, finish quality, accessories, and packaging to ensure flawless delivery.

Thanks to our multi-step QC system, Ridewave paddle boards are trusted by distributors, rental companies, and SUP brands in over 30 countries. Whether you're launching a new line or scaling your business, Ridewave gives you quality you can count on.

SUP Factory Production Team

The technical team is responsible for developing all types of samples-initial prototypes, showroom samples, pre-production samples-and ensures that bulk production stays consistent with approved standards. They also oversee construction details, branding placement, and material specs.

Before each bulk order begins, our production department organizes a full pre-production meeting involving all key teams to align on every technical file and delivery requirement. This helps us control the production cycle and avoid costly delays.

Other team members handle tasks like drop-stitch cutting, digital templating, valve placement, lamination, inflation testing, and final QC packaging. Everyone plays a vital role in the Ridewave production ecosystem.

At Ridewave, the factory exists because of our people-and our people take pride in every board they build.

Whether you're launching a private label or scaling your brand globally, Ridewave's united production team is behind you every step of the way.