How To Design A Paddle Board That Sells

Jun 19, 2025

Leave a message

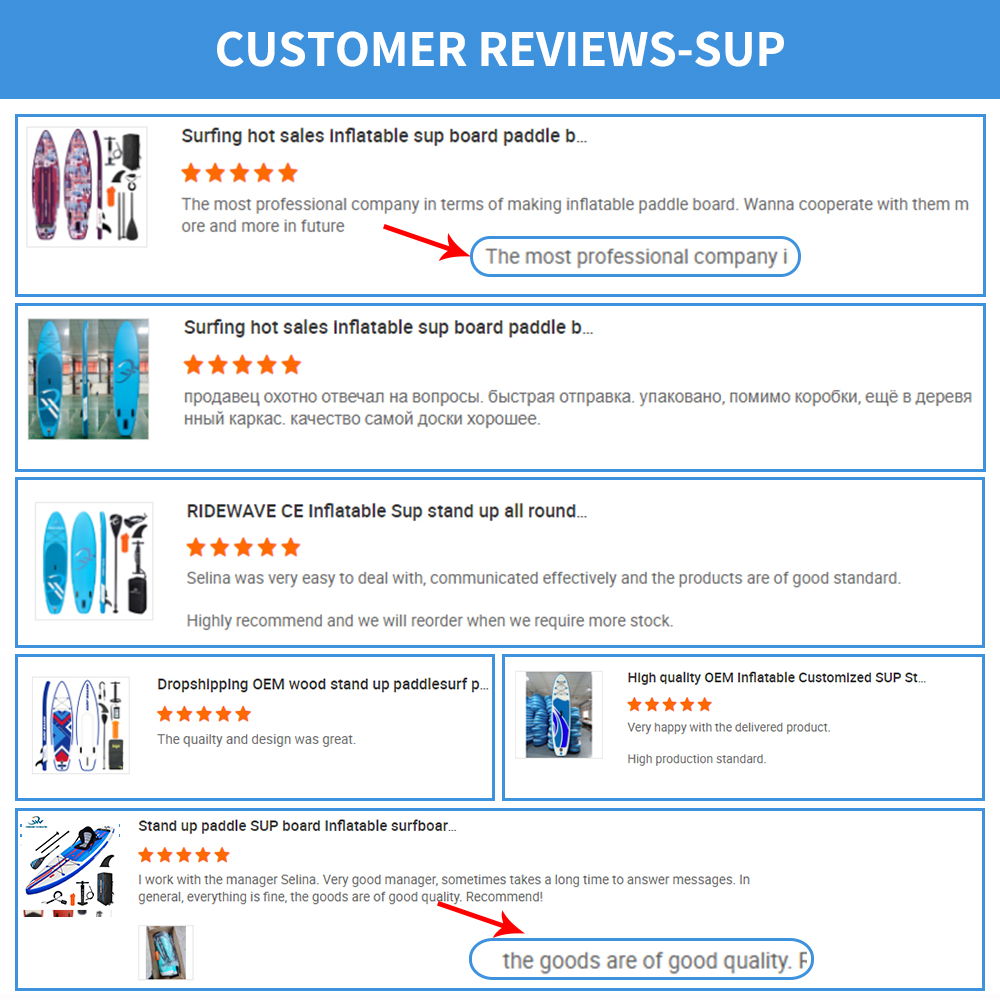

In today's competitive water sports market, a well-designed paddle board can make the difference between a best-seller and a poor performer. Whether you're a startup brand, a distributor, or a rental business owner, creating a paddle board that truly meets market needs is key to your success. Design isn't just about appearance-it's about performance, safety, comfort, and brand identity.

This guide will walk you through every step of designing a paddle board that sells. From market research to construction materials, from accessories to packaging, every detail matters. With insights from Ridewave-a leading SUP manufacturer trusted by over 200 global partners-you'll learn how to bring high-demand boards to market quickly and confidently.

Understand Your Paddle Board Target Market

A board that sells starts with knowing who you're selling to. The paddle board market includes:

Recreational users: Value stability, affordability, and easy use.

Rental operators: Need rugged, long-lasting boards that can handle frequent use.

Retailers: Look for appealing designs with great margins.

Adventure seekers: Demand speed, tracking, and portability.

To design the right product, ask:

What size and weight range does my audience need?

Are they beginners or experienced riders?

Which climates and water types will they use the board in?

Ridewave Tip: We help partners collect and interpret market data to match board specs to local demand.

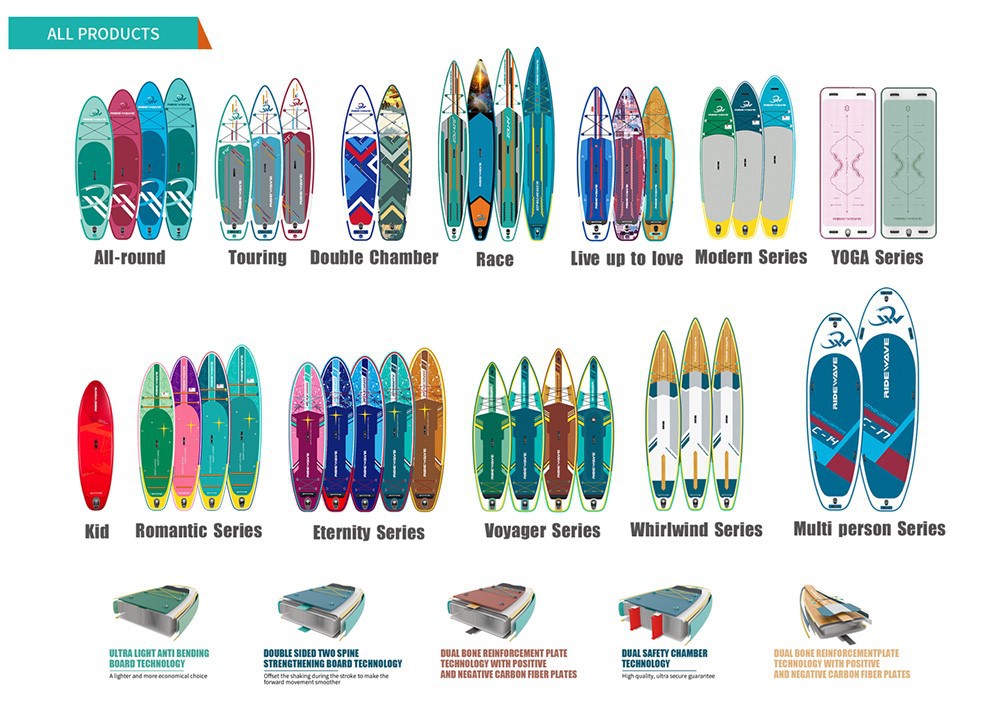

Define the Right Paddle Board Type

Choosing the correct paddle board type is essential. Each type targets a different user group:

All-around (10'6"): Most versatile; ideal for general use.

Touring (11'-12'6"): Great for long-distance paddling.

Yoga boards: Wider and more stable for workouts.

Race boards: Longer, narrower, faster.

Kids' boards: Shorter, lighter, easier to maneuver.

Also consider thickness (4" vs. 6") and width (30"–34").

Ridewave Case: 10'6" all-around boards are our most popular starting point for B2B customers due to their broad appeal and easy customization.

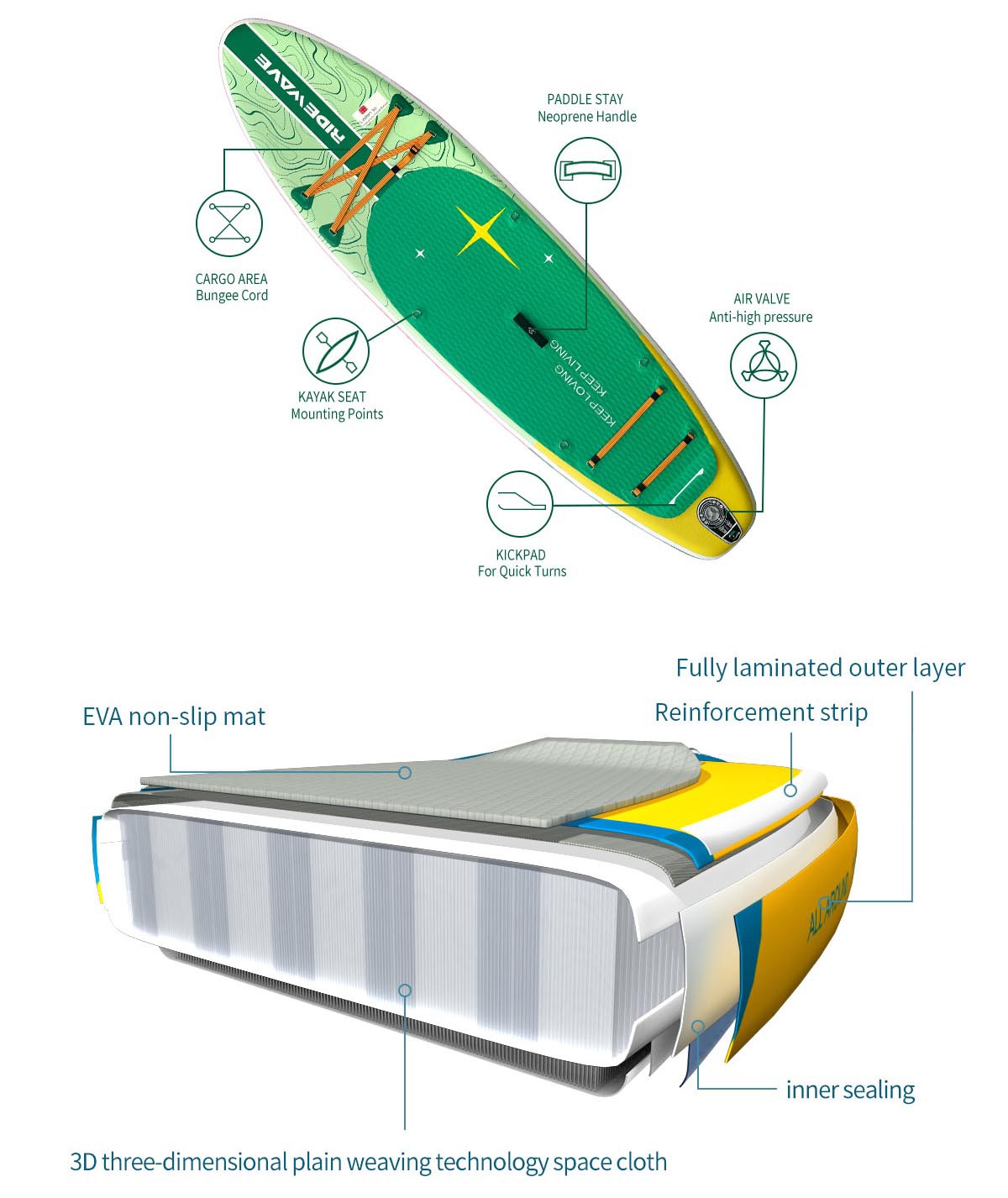

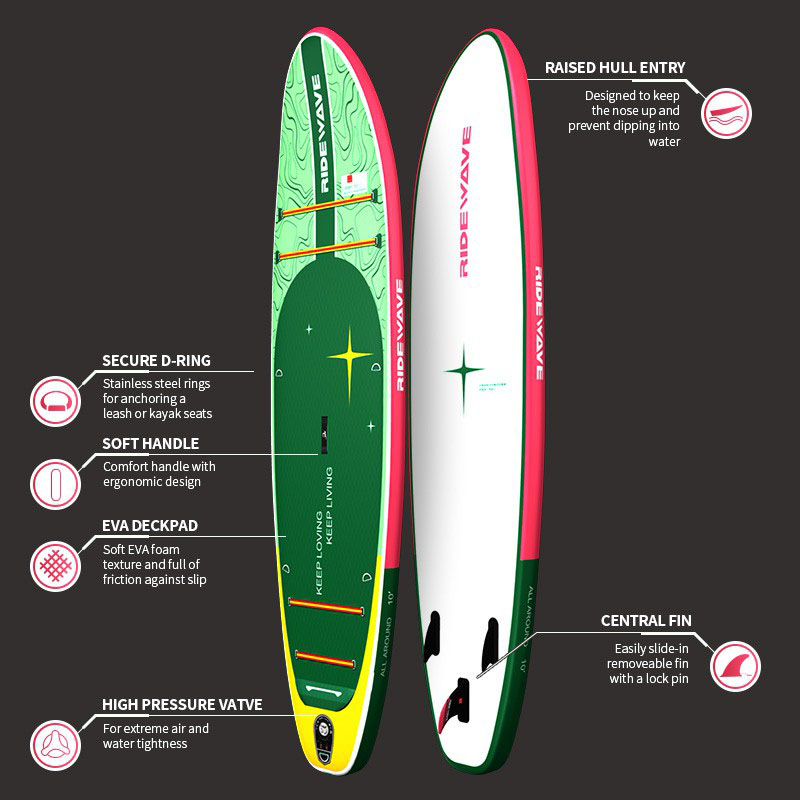

Focus on Paddle Board Materials and Construction

Your paddle board's quality depends on its core materials and construction method. Key materials include:

PVC layers: Single-layer for lightweight, dual-layer for durability

Drop-stitch core: Holds the board's shape under pressure

EVA deck pad: Non-slip and cushioned for comfort

Construction methods:

Fusion Technology: Laminates layers with heat, reducing glue use

Woven drop-stitch: Stronger and lighter than knitted types

Dual chamber: Adds safety and stiffness, great for rentals and touring boards

Ridewave Innovation: In 2010, Ridewave introduced the I-shaped double-layer isolation wall. In 2013, we pioneered dual chamber design-updated in 2019 for better air separation and pressure.

Design Paddle Board for Performance and User Experience

Design isn't just visual-it's about how the board handles and feels. Important details include:

Board shape: Round nose = stability; pointed nose = speed

Fins: 3-fin setup for tracking; single fin for rivers or yoga

Deck pad: Full-length for yoga/fishing; diamond-cut for grip

Handles & bungees: Add function and improve portability

Ridewave Design Tip: We offer full customization on deck pad texture, color, and placement of handles/D-rings to enhance usability.

Paddle Board Aesthetics and Branding

A well-branded board attracts attention and builds recognition. Focus on:

Color psychology: Blue = calm, orange = energy, black = premium

Logo placement: Top deck, side rail, and paddle recommended

Accessory matching: Align paddle, leash, and backpack design

UV resistance: Protects print and color from fading

Ridewave Bonus: We help brands create a visual identity that extends from the board to all accessories.

Paddle Board Prioritize Packability and Packaging

A high-quality board should be easy to pack, ship, and store. Consider:

Inflation/deflation time: Faster pumps = better user experience

Carrying options: Backpacks vs. rolling bags

Shipping box design: Size affects freight cost and product protection

Ridewave Packaging Advantage: We use a dual-wall construction box with optimized dimensions to reduce damage and increase container efficiency.

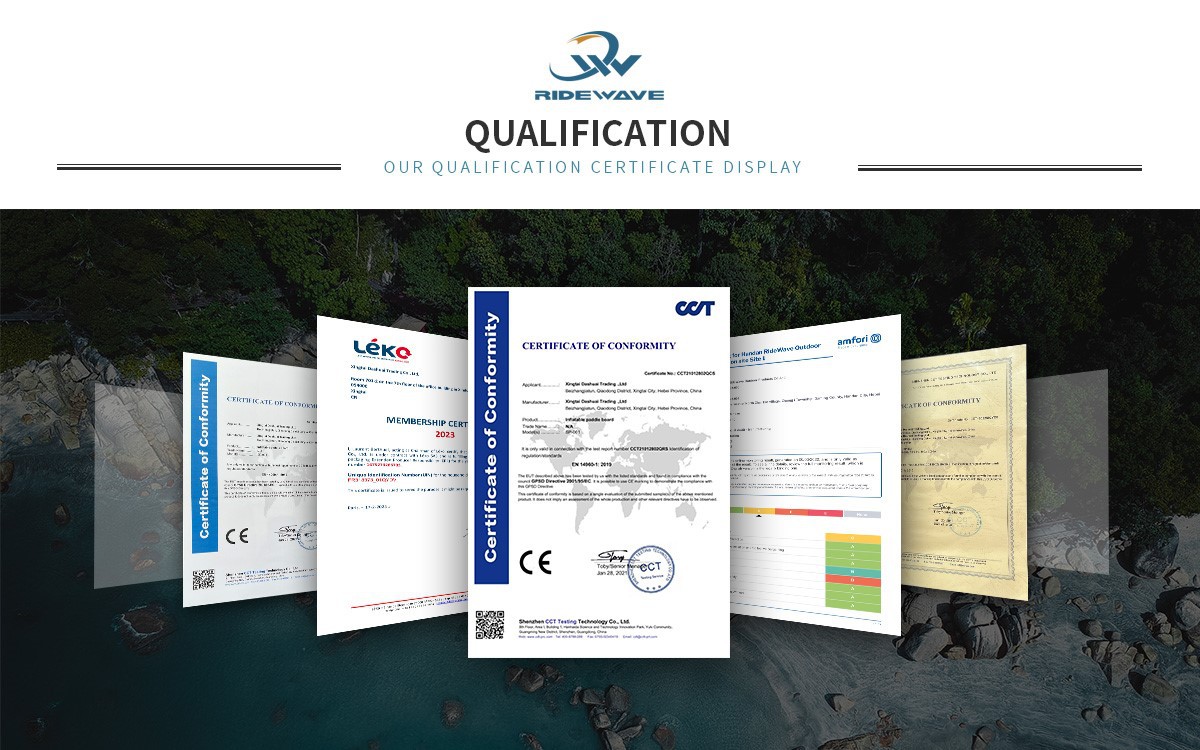

Paddle Board Compliance and Safety Features

Safety builds trust. Your board should meet international safety and durability standards:

Pressure, UV, and impact testing

Anti-slip deck texture

Clear user instructions and warnings

ISO/ASTM/EN compliance labels

Ridewave Commitment: Every board is pressure-tested for 72 hours before shipping. We also offer CO, REACH, and CE certifications.

Get Paddle Board Prototyping Feedback Early

Work With a Paddle Board Manufacturer That Supports Innovation

Designing a board is hard alone. Choose a partner who can:

Turn concepts into CAD files

Provide market feedback and testing support

Offer ODM options if you want to move fast

Ridewave OEM/ODM Strength: We offer 30+ in-stock ODM designs and full OEM customization from shape to packaging.

A great paddle board is more than a floating platform-it's a user experience, a brand message, and a product with purpose. By focusing on user needs, material quality, branding, and manufacturing support, you can create a board that not only looks good but sells well.

Ridewave is here to support you at every step of your paddle board journey-from design to delivery. Let's create something that stands out in the water and in the market.

Related Articles You May Like

If you enjoyed this guide, check out these other in-depth articles to grow your paddle board business:

1.Top Features B2B Buyers Should Look for in a Paddle Boards Manufacturer

2.How to Build a Paddle Board Brand: The Ultimate B2B Success Roadmap

3.OEM vs. ODM: Which Is Better for Your SUP Business?

4.Common Mistakes to Avoid When Importing Paddle Boards from China

5.How to Choose the Right Paddle Boards for Your Rental Business

6.Why More Paddle Board Distributors Are Choosing Ridewave in 2025

Explore these to unlock deeper insights into branding, sourcing, and scaling your SUP product line.