From Design To Delivery: The Ridewave SUP OEM & ODM Advantage Explained

May 21, 2025

Leave a message

In today's fast-growing stand-up paddle board (SUP) industry, competition is fierce and speed to market is everything. For brands and distributors, choosing the right OEM or ODM partner can make all the difference. OEM (Original Equipment Manufacturer) services allow businesses to produce SUPs under their own brand, while ODM (Original Design Manufacturer) services offer full product development support from concept to launch.

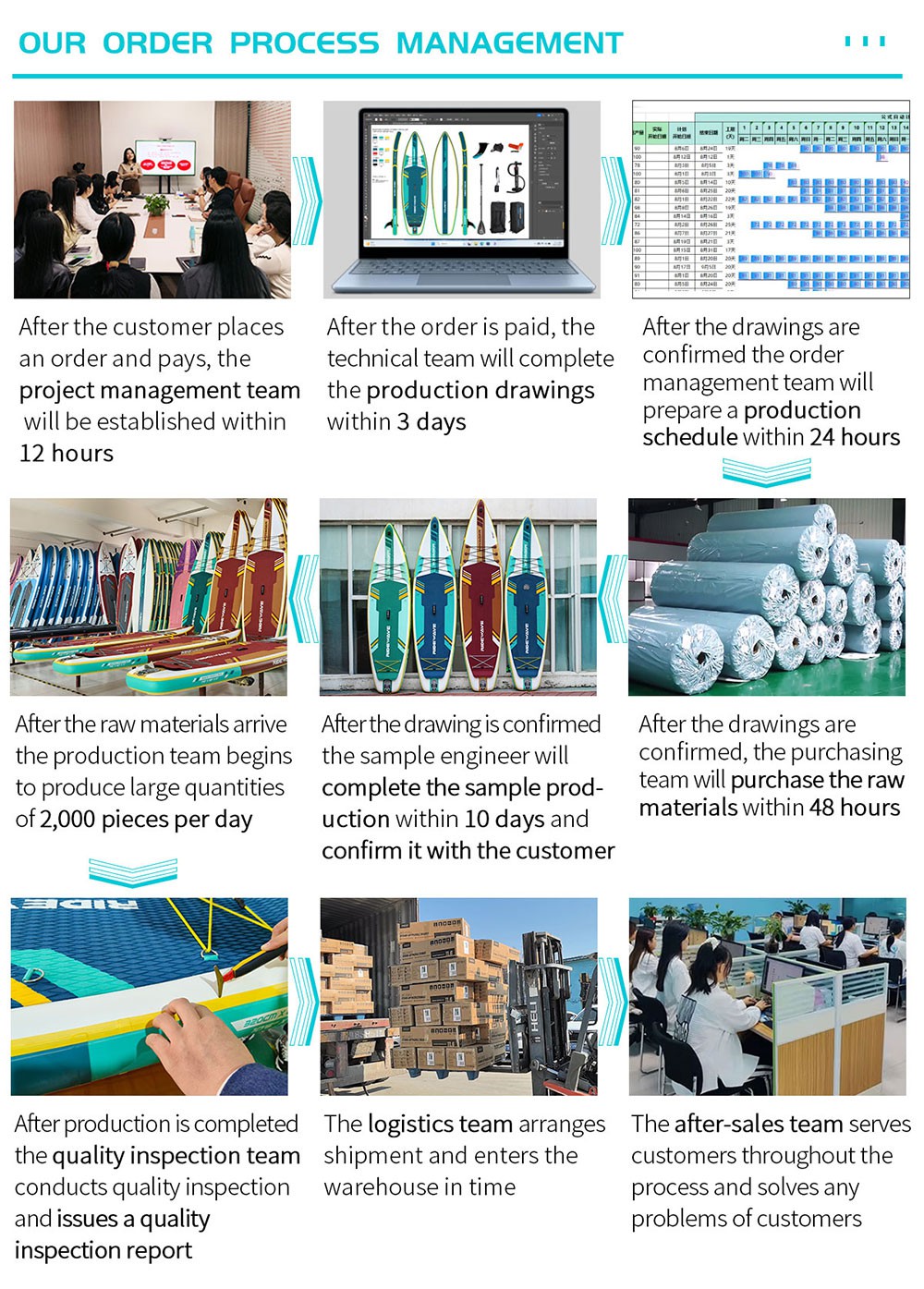

Ridewave, a leading inflatable SUP manufacturer based in China, has become the trusted partner for hundreds of global businesses in 2025. From initial sketches to final delivery, Ridewave's OEM and ODM solutions provide reliability, customization, and speed.

OEM focuses on manufacturing according to the client's design, while ODM involves Ridewave designing the entire paddle board model based on market trends or client inspiration. For example, if you already have a board design and just need production, OEM is perfect. But if you're starting a new brand without design capability, ODM gives you ready-made solutions.

Ridewave supports both models flexibly. Many clients begin with ODM to launch quickly, then gradually move into OEM as their branding grows. With Ridewave's in-house designers and engineers, clients enjoy seamless project handling.

Customized SUP Design: Turning Ideas into Market-Ready Products

Customization is at the heart of Ridewave's OEM & ODM services. Clients can personalize board shapes, sizes, colors, deck pads, valve positions, and handle types. ODM clients benefit from Ridewave's ready-to-go board templates based on market analysis.

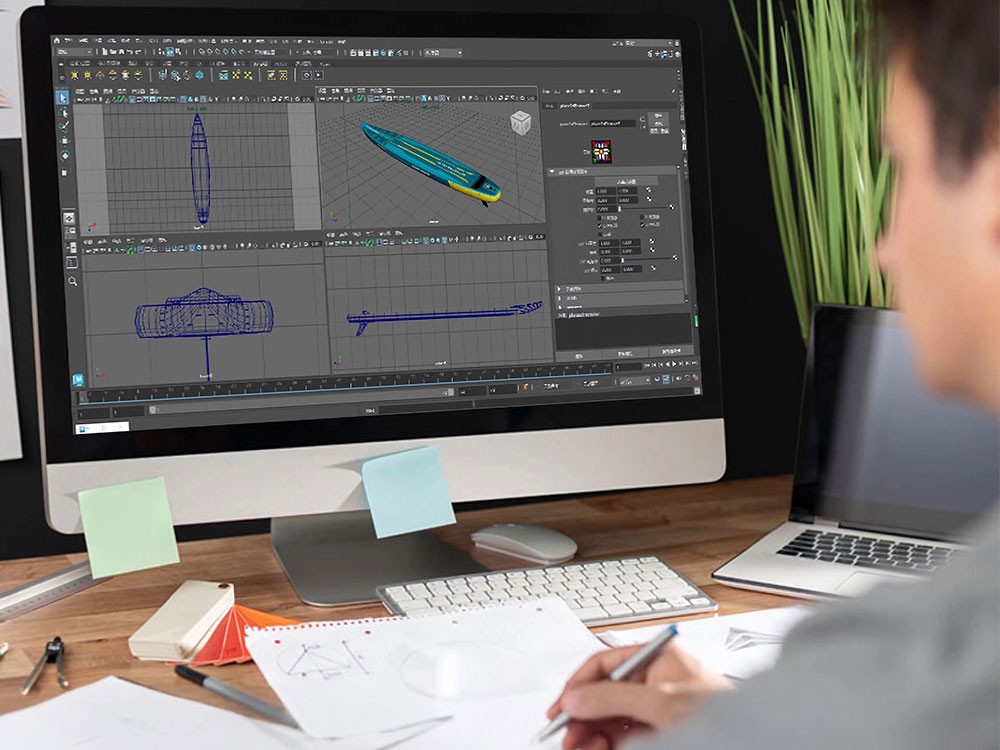

Whether it's a minimalist design for Scandinavian markets or vibrant, tropical graphics for the Australian market, Ridewave's design team transforms ideas into prototypes. Using 3D renderings and mock-ups, clients can visualize their products before production starts.

Material Sourcing & Construction: Quality Starts from the Core

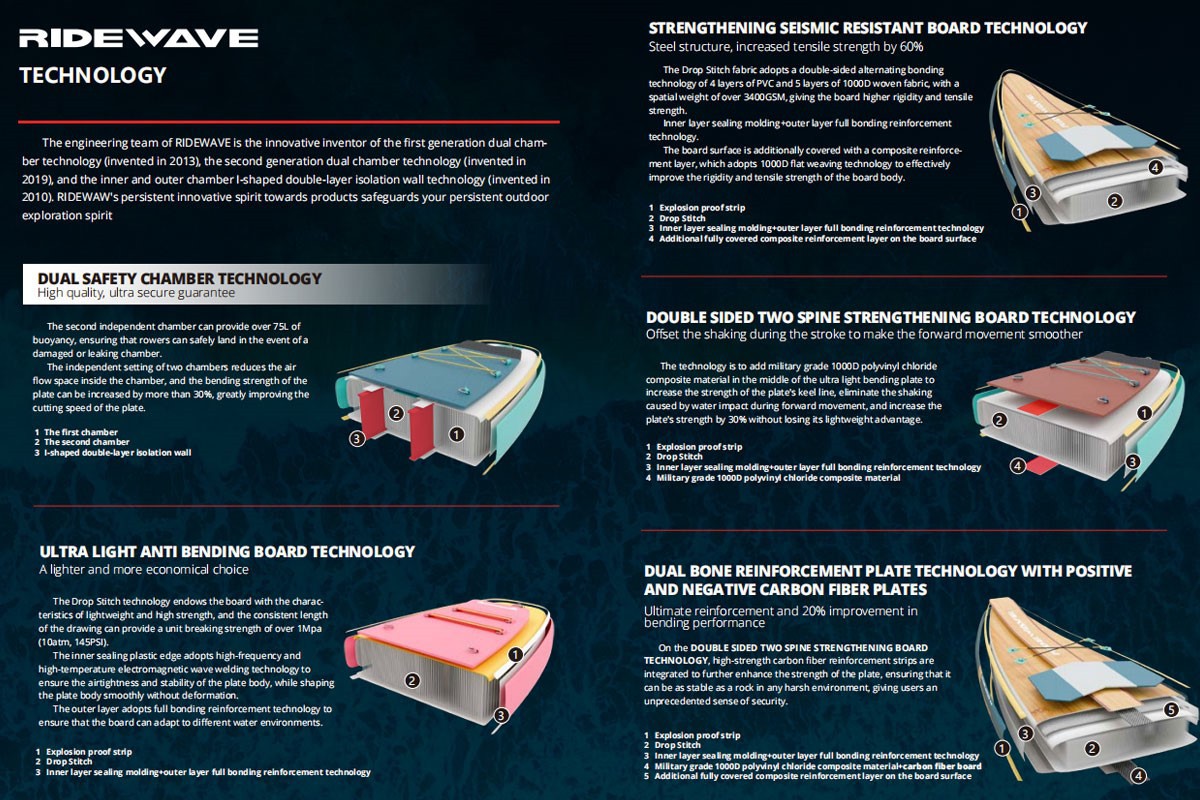

Every great SUP starts with top-tier materials. Ridewave uses advanced drop-stitch cores, double-layer fusion technology, and UV-resistant PVC. The company carefully selects each raw material supplier to meet strict durability and performance standards.

Clients can choose between lightweight, performance-focused constructions or ultra-durable builds suitable for rentals. Whether it's your OEM design or a Ridewave ODM board, the same high-quality materials apply.

SUP R&D Capabilities: Prototyping and Sample Validation

Before going into full production, Ridewave offers fast prototyping services. Once the design is confirmed, samples are made within 7–10 working days. Customers can test the samples, provide feedback, and make revisions.

Ridewave also offers remote video sample reviews for overseas clients, saving time and shipping costs. With 20+ R&D engineers and a dedicated sampling line, Ridewave ensures that every board looks and performs as expected.

SUP Brand Identity: Logos, Prints, and Packaging That Sell

Ridewave enables brands to shine with high-resolution custom logos, heat transfer graphics, silk screen prints, and eco-friendly packaging. For OEM clients, your board becomes a true extension of your brand. For ODM clients, Ridewave can help develop logo ideas, color palettes, and packaging themes.

Packaging includes branded board boxes, user manuals, and accessories kits-delivered retail-ready. With Ridewave, your SUP doesn't just perform well; it looks premium and consistent on the shelf.

A paddle board alone is rarely enough for a complete paddling experience. Most customers today expect full paddle board kits, especially those purchasing online or from retail stores. That's where Ridewave's accessory integration sets us apart.

Ridewave provides a wide selection of high-quality accessories that can be bundled with each SUP board, turning a basic product into a retail-ready package. Accessories include adjustable aluminum or fiberglass paddles, dual-action high-pressure hand pumps, ankle safety leashes, carry backpacks, waterproof phone pouches, kayak seat attachments, repair kits, and detachable fins. Each of these can be fully customized with your logo, brand colors, or packaging.

For OEM clients, Ridewave tailors accessory kits based on your specific design and audience. For example, performance-focused SUP brands may want to offer lightweight carbon paddles, whereas rental businesses might prefer rugged 3-piece aluminum paddles. ODM clients benefit from Ridewave's data-driven recommendations: we analyze global retail and ecommerce trends to suggest the best-selling accessory combinations in each market.

More importantly, Ridewave ensures that all accessories are packaged efficiently to reduce shipping costs without compromising presentation. Many clients use our all-in-one packaging design-an approach that simplifies shelf stocking and enhances the unboxing experience.

The all-in-one retail solution gives your brand a polished, professional appearance, right out of the box. It's ideal for ecommerce sellers, distributors, and stores who need plug-and-play SUP packages that are ready to delight customers from day one.

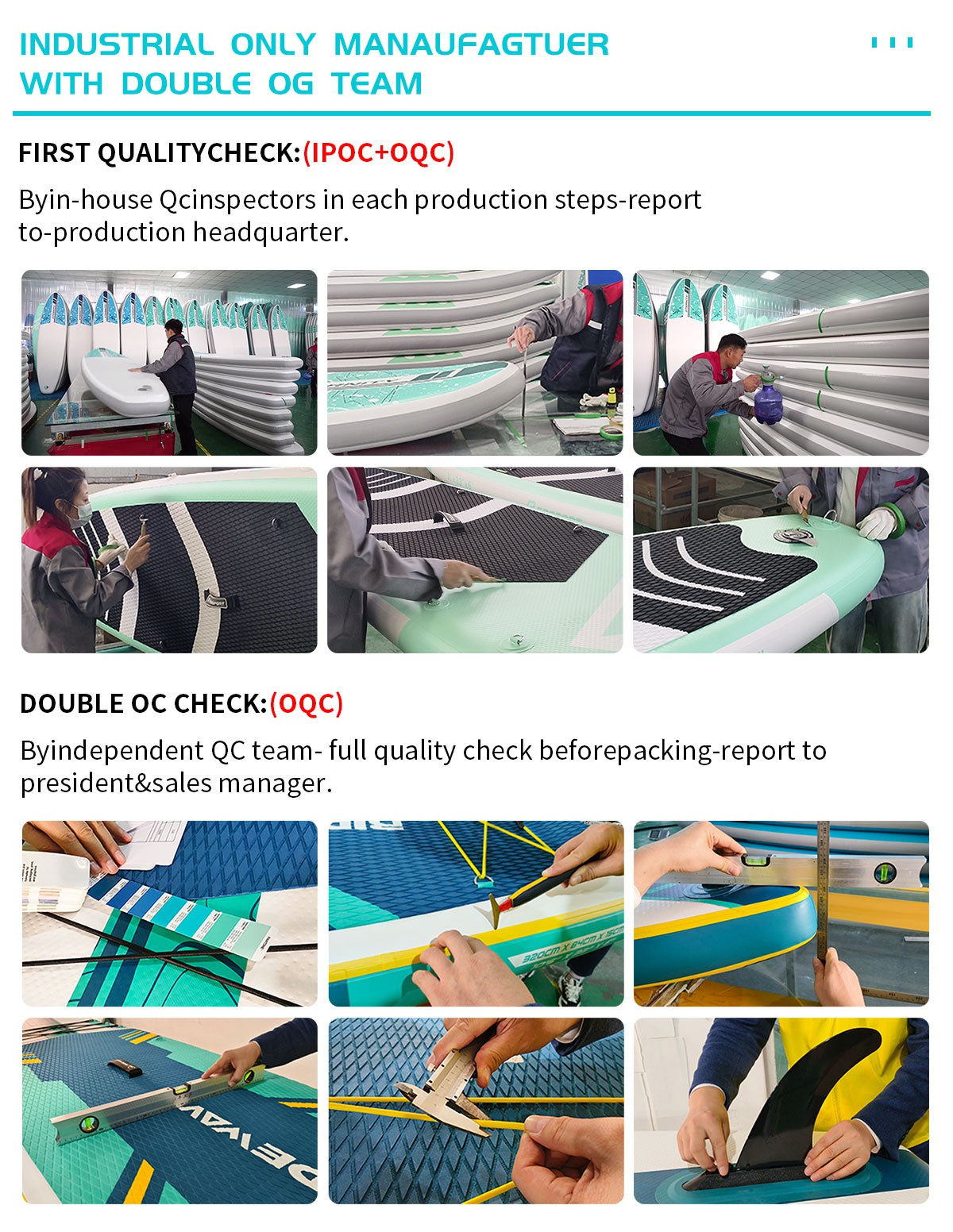

Ridewave has earned a strong reputation in the paddle board industry not just for its designs, but for uncompromising quality. At the heart of our manufacturing process is a rigorous five-step quality control (QC) protocol that ensures every board meets global standards.

Step 1: Material Inspection – Before production begins, raw materials (PVC, drop-stitch fabric, EVA pads, etc.) are tested for thickness, flexibility, and consistency. Only certified suppliers are used.

Step 2: In-Process Monitoring – During assembly, each production line has a dedicated QC member overseeing adhesion, valve installation, and alignment to prevent errors early.

Step 3: 72-Hour Inflation Test – Every board is inflated to 15–18 PSI and left under pressure for 72 hours to detect any leaks or pressure loss. This step ensures the durability and reliability of every SUP.

Step 4: Final Appearance Inspection – Boards are examined for graphics alignment, cleanliness, smooth seams, and logo clarity. Aesthetics are as important as performance.

Step 5: Accessory and Packaging Check – Each accessory is inspected before being added to the packaging. Cartons are then checked for labeling accuracy and packing safety.

Clients can request live video inspections or third-party audits for added peace of mind. With over 15 full-time quality control inspectors and ISO-certified systems in place, Ridewave guarantees that what you see in the sample is exactly what you'll get in production-whether your order is 100 units or 10,000.

SUP Low MOQ, Fast Turnaround: Flexible Manufacturing for All Scales

One of Ridewave's most appreciated advantages is its ability to support businesses of all sizes. Whether you're a startup brand testing a niche market or an established distributor with a full product line, Ridewave's flexible manufacturing model empowers you to scale on your terms.

We offer a low minimum order quantity (MOQ) starting from just 50 boards per design. This is especially valuable for:

New businesses looking to minimize initial investment

Seasonal brands targeting holiday or summer-specific launches

Retailers wanting to test different graphics or models without overstock risk

Our standard production timeline is 25 to 35 days, depending on board complexity and customization level. For urgent needs, Ridewave offers priority production slots, ensuring delivery within 15–20 days for small to medium runs.

Even better, Ridewave's batch consistency is exceptional. Clients often report reordering months later with zero variance in color, logo quality, or board performance. This consistency reduces customer complaints and increases your brand credibility.

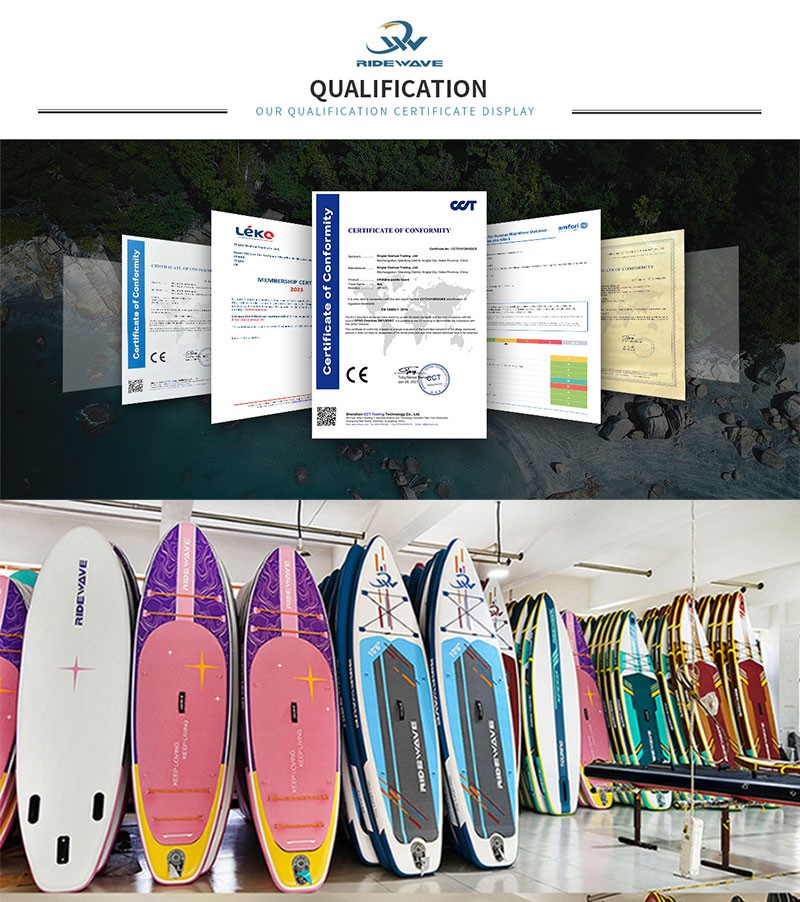

In today's safety-conscious, regulation-driven global market, compliance is key. Ridewave ensures that every board we produce meets international safety, quality, and environmental standards-giving clients peace of mind and smooth import clearance.

All Ridewave products can be delivered with the following certifications upon request:

CE – For sales in the European Union

RoHS – Ensuring no hazardous substances in materials

REACH – Complying with EU chemical safety guidelines

ISO 9001 – Quality management system certification

EN 15649 – Safety standard for inflatable watercraft

For ODM models, we pre-design boards to align with these standards, making them especially appealing to distributors in tightly regulated regions like Germany, Canada, and Australia. OEM clients can also request tailored compliance testing based on their destination markets.

Ridewave assists with all required MSDS reports, COAs, barcodes, labeling, and shipping documentation, helping ensure your SUP shipment clears customs smoothly and quickly.

SUP's Shipping & Logistics: From Factory to Global Warehouses

At Ridewave, we know that producing great boards is only part of the job. Ensuring those boards reach you safely, affordably, and on time is equally critical. That's why we offer end-to-end shipping and logistics services tailored to your needs.

Our logistics team supports multiple shipping terms:

FOB (Free On Board): You or your freight forwarder arranges pickup at our warehouse

CIF (Cost, Insurance, and Freight): We deliver to your nearest port

DDP (Delivered Duty Paid): We manage the entire delivery, including customs clearance and duties

We ship to over 40 countries with experience in managing:

Amazon FBA shipments (labeling, carton sizing, barcode placement)

Retail distribution centers with strict delivery window requirements

Ocean, rail, air, and hybrid freight options

SUP's After-Sales & Long-Term Support: Beyond Just Manufacturing

Unlike many factories that disengage after shipping, Ridewave is committed to building long-term relationships. We believe that after-sales service is just as important as design and production.

Here's how we continue to support our OEM and ODM clients:

Product Manuals & Tutorials: We provide multilingual user manuals, inflating/deflating guides, and maintenance tips.

Marketing Assets: ODM clients receive professional product photos, lifestyle imagery, and social media templates.

Warranty & Repair Support: We guide clients through troubleshooting, spare parts shipping, and warranty policies.

Client Feedback Loop: Feedback from your customers helps improve future board batches.

Our account managers maintain regular contact and provide seasonal updates, new model recommendations, and trend insights. Many of our clients have worked with Ridewave for over five years-not just because of the quality, but because of the trust and consistency we provide.

From design sketch to retail shelf, Ridewave makes the journey smooth, reliable, and scalable. Whether you need a unique shape, eco-friendly board, full accessory bundle, or FBA-compliant logistics-we're the behind-the-scenes partner helping you shine.

If you've found this guide helpful and are considering starting or scaling your paddle board brand, don't hesitate to contact the Ridewave team for a quote, sample, or project consultation.

Related Articles You May Enjoy

Why Russian Paddle Board Distributors Trust Ridewave for Fast & Reliable Production

Canada's 2025 SUP Trend: Why Distributors Are Embracing Inflatable Boards

How to Customize Your SUP Brand: Colors, Prints, Packaging & Accessories That Sell

Low MOQ, Fast Shipping: The Perfect SUP Partner for Spain Importers

OEM vs. ODM: Which Is Better for Your SUP Business?

The Future of Inflatable SUP Manufacturing: Materials & Methods